- Home

- Products

We are one of the leading manufacturers and suppliers of bulk material handling systems. These are acknowledged for optimum performance, long functional life, low maintenance, high efficiency and sturdy construction.

Raw sugar is being imported from sugar producing nations and they are refined in india and exported back to many countries. shri Ramana is pioneer in handling this raw sugar at afforable cost and also innovatively to meet capacity targets.

Ask for Price

Shri Ramana was the first company in india to build a side wall cleated belt conveyor using india made belt and today boasts many installation throught the country.

Ask for Price

Bridge type stacker and reclaimer are typically low budget alternatives to market availble stacker and reclaimer. they provide enormous flexibilty in operation. more over for the given area they stack more material than other type of stacker and reclaimer. more than anything it calls for zero maintenance and operator dependance.

Ask for Price

Shri Ramana has specialised in bag handling conveyors especially for sugar mills, fertiliser factories, Cement Factories and sponge iron industries. many godowns in india are using shri ramana bag Conveyors as they are sleek and ergonomically designed.

Ask for Price

Shri Ramana slat chain conveyors are working in most power plants sugar plants and paper mills. some of the conveyors are running for more than 26 years without major breakdowns. all conveyors are having safety protection, overload protection and certain fail safe design built-in.

Ask for Price

Coal handling has been Shri Ramana group favourite subject from inception. it all started with 5tph to today 3000 tph capacity meaning a graduated growth story with rich experience in all the fronts.earlier coal handling system especially for fluidised bed boilers was used to be nightmare for end users. this was totally solved and today the chp can be run unmanned considering automation and reliability combined with innovation.

Ask for Price

Live grizzlies prove greatly beneficial to handly truck tippled coal so that the bigger lumps move automatically to one end allowing right size lumps pass through. this enable chp to handle large capcities without the need for breaking bigger lumps.

Features:

Best In quality

Effective Cost

Ask for Price

Ship loaders are developed in house with least cost and at the same time with innovative ideas so that it performs smoothly with any type of vessel.

Ask for Price

Shri Ramana developed coal crusher for small capacities and are running well in chp.

Ask for Price

Silos and bunkers in hundreds were built by shri ramana. whether circular,square,rectangular, symmetrical or assymmetrical ground level or at a height of 54 meters capacity 1 ton or 5200 tons material low density husk or high density iron ore all are handled to the satisfaction of end users. they work under cyclone earth quake conditions for years.

Ask for Price

There were only 4 companies worldwide have developed paddle feeders till 2003. shri ramana became 5th company to develop this machine under the request from l&t for their tata steel project at jamshedpur for 2000tph iron ore. if you keep 4 machines developed by others in one row and shri ramana in another row you will find all the four are similar in look with minute difference in the design. whereas shri ramana design is totally different and modular in shape adding excelelnt strength with one third of weight of other designs.

Ask for Price

Sine wave resonance screen is actually a screen which was designed primarily to reduce noise, to reduce power consumption and also provide higher efficiency using resonance theory.

Earlier this kind of technology was used in different fields, but today this technology has been utilized by us in bulk material handling. the available resonance screen provides a parametric oscillation to the screen. while sine wave screen actually provides a linear oscillation in the longitudinal direction of the mesh. the mesh is held tightly across the length of the system using an automatic tension system. the vibrator holds the screen at minimum spots and provides a sine wave flow to the material. mainly used for moist coal to pass through less than 6mm aperture.

Ask for Price

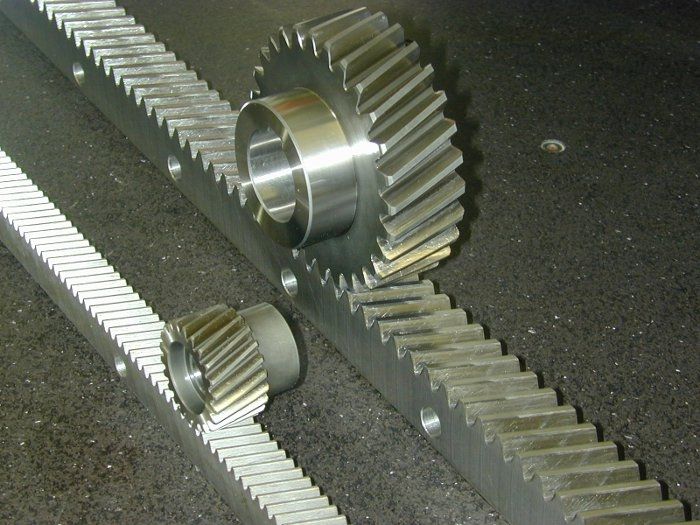

| Belt Conveyor | Roller Conveyor | Reversible Conveyor |

| Chain Conveyor | Flight Conveyor | Travelling Tripper |

| Redler Conveyor | Portable Conveyor | Shuttle Conveyor |

| Drag Chain Conveyor | Screw Conveyor | Bucket Elevator |

| Submerged Belt Conveyor | Wire Mesh Conveyor | Cleated Belt Conveyor |

| Apron Conveyor | Swiveling Conveyor |

Ask for Price

| Apron Feeder | Screw Feeder | Lump Breaker |

| belt feeder | Table Feeder | Paddle Feeder |

| Drag Chain | Rotary Vane Feeder | Rotary Airlock Feeder |

| Feeder |

Ask for Price

| Resonance Screen | EOT Crane stacker | Storage Stacker |

| Circular Motion Screen | Radial stacker | Lorry Loaders |

| Linear Motion Screen | Bag Loading Stacker | Ship Loaders |

| Motorised Mobile | Bridge Loading reclaimer | Live Grizzly |

Ask for Price

| Idlers | Screw Takeup | Screen Mesh |

| Pulleys | Scrapers | Elevator Buckets |

| Tension Rollers | Rotary Brush | Hold Back |

| Screw Conveyor hanger Bearing | Hood | Screen Components |

| Screw Conveyor screw |

Ask for Price

- Raw material prepartion and handling systems.

- Fine Coal/Lignite preparation/ash Handling systems

- Bagasse/Wood Chips handling systems

Ask for Price